Summer Dye Experiments: Sequoia, Madder, Marigold & Cutch

/With this batch of natural dye experiments I wanted to finish with more than a pile of colourful swatches and trims to add to my stash, so I decided the theme of this dye weekend would be to make a table setting for a late summer dinner party. I thought along side that I could make a set of tea towels for the kitchen, and the napkins I made would be a smaller "everyday" style napkin that could be used instead of paper napkins when eating all of our meals at home. So a table cloth, tea towels, and napkins was the plan, and of course a pile of swatches to add to my stash because why not throw any extra bits of fabric in when you have the dye pot going.

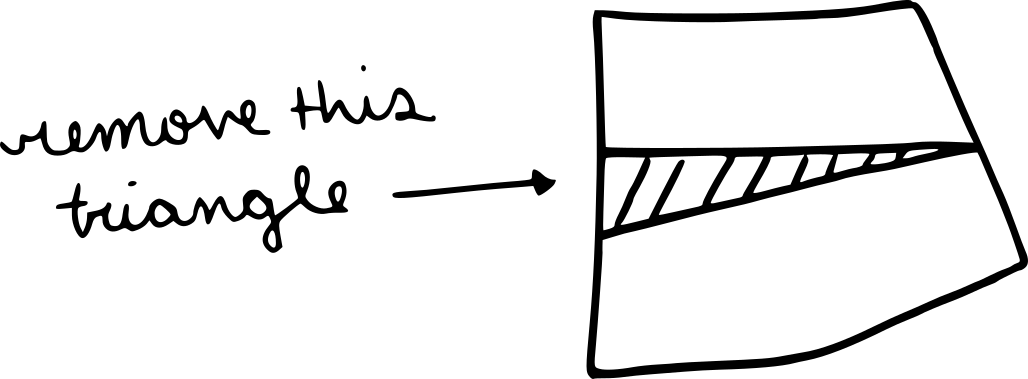

So before I even got started with the dyeing I had to make the things I wanted to dye. The table cloth I made by hemming two large pieces of linen and then adding buttons and buttonholes, which allowed the pole of our umbrella to come up through the two pieces. And then 16 tea towels and 16 napkins took me a couple weeks to finish, following the metered corner tutorial from Purl Soho (link to tutorial at the end of this post).

I made 4 dye pots, as always following the free instructions from Maiwa as closely as I could. Below WOF is an abbreviation for "weight of fabric", which is how dye stuff is measured when natural dying.

Cutch:

Measured at 30% WOF. No tannin is needed for cutch so I just scoured the fibres and mordanted with alum at 15% WOF, then a second alum mordant at 10% WOF. The table cloth went into this dye bath and it made such a beautiful brown. This is the dye from this summer that I am most looking forward to learning more about in the future, as there are so many ways to shift the colour by adding things to the dye bath as you work.

Cutch & Madder:

Cutch was measured at 45% WOF and Madder at 15% WOF. No tannin is needed for cutch so again I scoured the fibres and mordanted with alum at 15% WOF, then a second alum mordant at 10% WOF. I was hoping for a deep rust colour, and I like the reddish brown that I got but I'm still going to work towards a more perfect rust colour.

Marigold & Madder:

Marigold measured at 45% WOF and Madder at 10% WOF. I scoured fibres, applied tannin at 10% WOF, mordanted with alum at 15% WOF, then again with alum at 10% WOF. This combination of dyes was just perfect, it made for an orangey gold colour and it's just so vibrant. One day I'll have a garden full of marigolds so that I can harvest and dry my own dye stuff, and dye all of my belongings gold.

Sequoia:

Measured at 10% WOF. I scoured fibres, applied tannin at 10% WOF, mordanted with alum at 15% WOF, then again with alum at 10% WOF. Sequoia is a dye with moderate lightfastness, which means it will fade if left in the sun. I do like the purple grey colour but I think I could achieve a similar colour using other more lightfast dyes with iron. I was expecting more of a wine colour so maybe I'll have to play with this one again, but probably at a higher WOF percent.

I took a couple pictures of everything put together on our patio, and of course made a couple new pages for my dye swatch book.

Pattern for mitred corner table linens: Purl Soho

Dye Supplies: Maiwa Natural Dyes

Linen I used: 140g/sm white linen

Natural Dye Instructions I use: Maiwa Guide to Natural Dyes